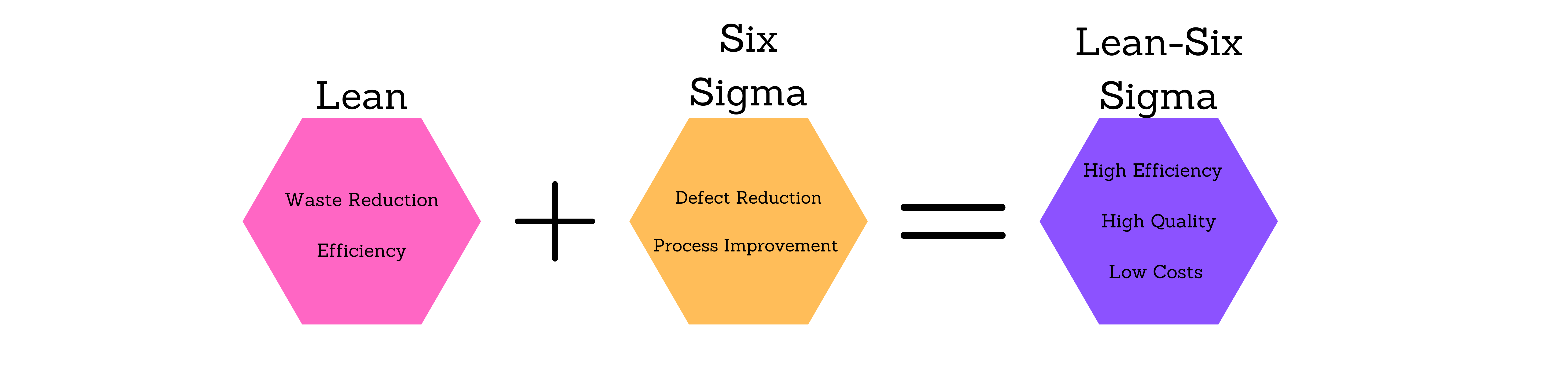

What is Lean-Six Sigma?

A systematic methodology utilizing DATA ANALYSIS techniques and process improvement tools

TO

Measure and improve a company’s performance measures

BY

Minimizing variations, defects and inefficiencies

TO

Meet and exceed customer needs

The Lean-Six Sigma Way

Improve process output metrics by:

Lean-Six Sigma = Best Quality, Lowest Cost, Shortest Time, Best Safety, and High Morale, through exceeding customer requirements and elimination of waste.

Classic Forms of Waste

Waste= non-value add

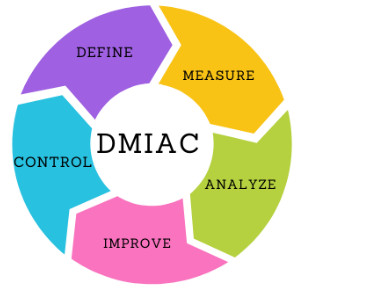

DMAIC Problem Solving

Define: Identify improvement opportunity

Measure: Measure current state of the process

Analyze: Identify causes of variation/defects/waste

Improve: Develop and implement new processes/methods

Control: Install controls to prevent reoccurrence of defects